In the fashion industry, cut and sew is a core garment production process. It directly impacts the quality of the finished piece and transforms your design sketches into reality.

However, the term is often misunderstood, with many confusing it with “private label” or “white label.” You might also be unsure how exactly it adds value to your children’s clothing line.

To answer these questions, I’ve created this complete guide to cut and sew. If you’re tired of compromising on quality and want to create unique products that perfectly match your brand vision, mastering cut and sew is your first step toward professional-grade production.

What is Cut and Sew

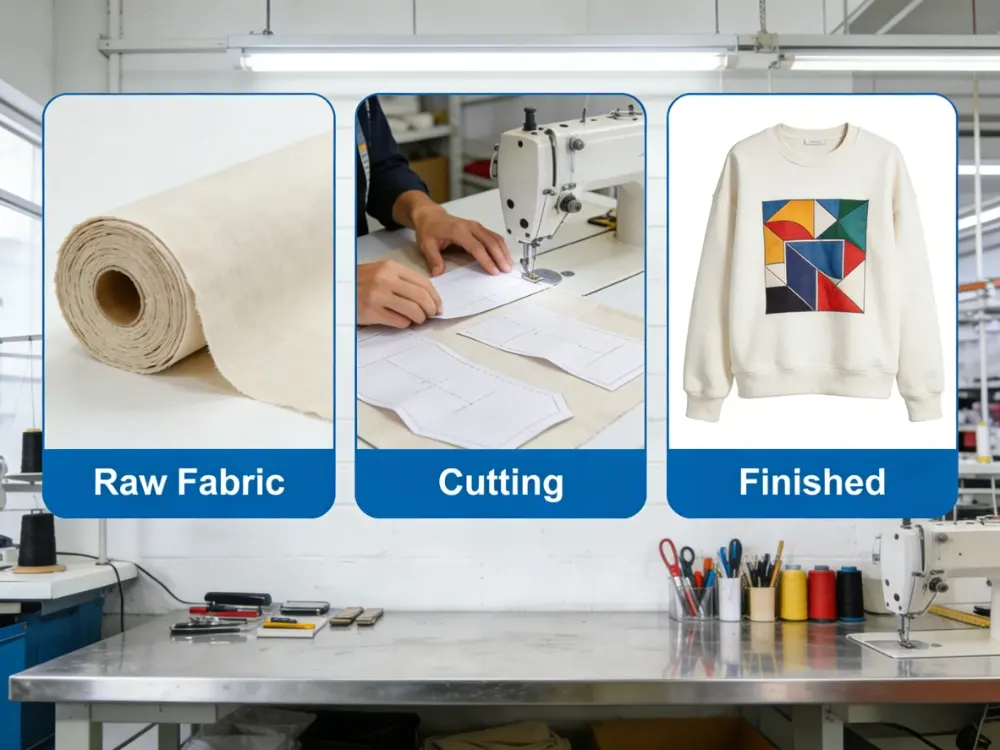

Cut and sew is a core garment manufacturing technique, and the key process for mass-producing children’s wear and ready-to-wear. It means making garments directly from raw fabric, rather than printing designs on pre-made blank apparel such as blank tees.

In this process, fabric is cut into specific shapes based on patterns and then stitched into finished products. It is the standard method for fashion brands and designers to create unique, custom clothing.

For example, if you want to sell cropped hoodies with extra-long loose sleeves, such custom designs are nearly impossible with standard pre-made blank hoodies.

This is where cut and sew becomes essential: you create a pattern with your ideal sleeve length and body width, lay it over the fabric, then cut and sew the pieces. This gives you a truly unique garment with an original, distinct fit.

Key Features of Cut and Sew

- Full Customization: You control every detail—from fabric type and silhouette to stitching, hardware (zippers, buttons), and exact measurements.

- Starts from Raw Materials: Production begins with rolls of raw fabric (often custom-dyed or knitted), not finished blank garments.

- Structured, Detailed Process: Before mass production, the workflow requires professional pattern making, grading (sizing), and sampling to ensure the perfect fit.

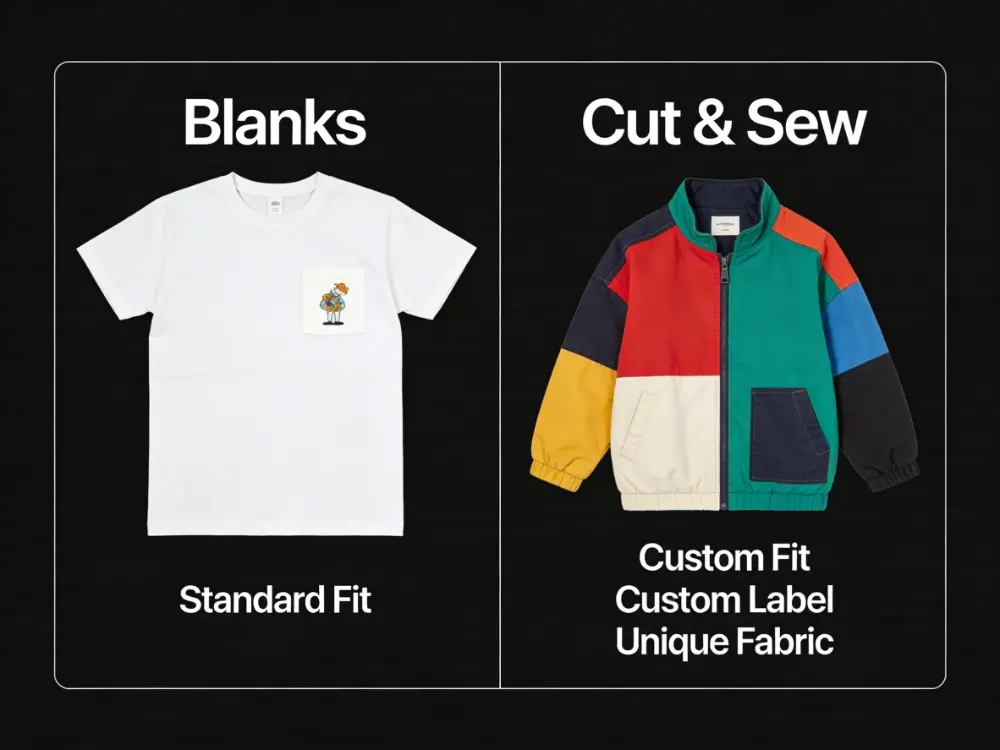

Cut and Sew vs. Blanks (Print-on-Demand): What’s the Difference?

Sure, both methods result in a shirt with your design on it. But here is the distinction: Cut and Sew is making the garment. Blanks are just decorating one that already exists.

Blanks (Print-on-Demand / Wholesale)

Here, you are essentially a decorator. You buy a finished product—think of it as a standard canvas—and apply your artwork to it. You are stuck with the canvas exactly as it is. It doesn’t change.

Cut and Sew

Here, you are a designer. You build the product from the ground up, tailored to your exact specs.

To make it crystal clear, I broke down the differences in this chart:

| Feature | Blanks (Print-on-Demand) | Cut and Sew |

| Product Shape | Standard. You pick from existing catalogs (e.g., standard fit, slim fit). | Custom. You decide the length, width, sleeve style, and neckline. |

| Fabric | Limited. You must use the fabric the manufacturer chose for that blank. | Unlimited. You source specific blends, weights, or textures. |

| Branding | Low. Often has the manufacturer’s tag (or requires effort to remove/replace). | High. Your own labels, custom hang tags, and branded packaging are standard. |

| Upfront Cost | Low ($). You pay per item when a customer orders. | High ($$$). You pay for patterns, samples, and bulk production upfront. |

| Risk | Low. No unsold inventory piling up in your garage. | High. If the design doesn’t sell, you are stuck with the stock. |

| Profit Margin | Lower. The base item cost is higher, eating into your profit. | Higher. The cost per unit is much lower in bulk, allowing more profit per sale. |

Why Choose Cut & Sew?

Unlike ready-made “off-the-shelf” blanks, Cut & Sew gives brands total control over every aspect—from fabric selection and fit to the smallest construction details.

This technique is especially valued in children’s wear, where parents prioritize comfort, safety, and durability above all else. However, the benefits extend far beyond that; whether for adult fashion or activewear, Cut & Sew delivers value that mass-produced garments simply cannot match.

Here are the 5 core wins you get with this method:

1.Fabric Safety & Ultimate Comfort

Ditch the scratchy, generic fabrics. You get to select premium materials straight from the source—think GOTS-certified organic cotton or soft bamboo. You can even go tagless to eliminate that annoying itch, solving sensitivity issues and elevating the entire wearing experience.

2.Flawless All-Over Prints

Say goodbye to unsightly white streaks and broken patterns at the seams. With the “print-then-cut” method, your design flows perfectly across sleeves and side seams. It creates a truly high-end, cohesive look that standard printing just can’t replicate.

3.Ergonomic, Custom Fit

Clothes should fit real bodies, not just be scaled-down squares. Whether you need extra “diaper room” and easy-on necklines for toddlers, or a specific silhouette for adults, custom cutting lets you tweak every dimension for real-world functionality.

4.Strict Safety & Compliance

You control the entire supply chain. Every button, dye, and trim can be vetted to meet strict standards like CPSIA and OEKO-TEX®. This eliminates chemical risks and physical hazards—which is non-negotiable when selling to parents.

5.Brand Power & Higher Margins

Unique cuts and fabrics build a moat around your business. Cut & Sew helps you break away from the “sea of sameness” in the market. It establishes a high-quality image that justifies a premium price tag and builds serious customer loyalty.

The Cut and Sew Manufacturing Process: Step-by-Step

Here is the exact path to building your Cut and Sew brand, taking you from a rough concept to a finished product on the rack:

Step 1: Pattern Making & Grading

This is the “blueprint” stage where your design vision becomes technical reality.A professional pattern maker creates a master template that defines the shape and fit of the garment. Using precise grading (mathematical scaling), the pattern is adjusted to ensure a perfect, consistent fit across all sizes — from 6M infants to active 5-year-old children.

Step 2: Sourcing Child-Safe Fabrics & Trims

In children’s wear, fabric safety is just as important as appearance.This step includes selecting soft, durable materials such as GOTS-certified organic cotton, and carefully choosing accessories that follow strict safety rules like CPSIA — including lead-free snaps and secure buttons — to protect sensitive skin and prevent choking risks.

Step 3: Sampling (Prototyping)

Sampling is your “insurance policy” against expensive mistakes in mass production.Before full production starts, a physical prototype is made to test fit, drape and durability.Only after the sample is washed, tested and approved (the pre-production sample) will the factory begin manufacturing, so the final product matches your exact expectations.

Step 4: Production & Quality Control

Once the design is finalized, skilled workers cut and sew the fabric with precision to create your inventory.The last stage is a strict quality control (QC) process, which includes:

- Checking measurements against the size chart

- Mandatory metal detector scanning to ensure no broken needles are left in the fabric

- This guarantees 100% safety for the end user.

Pros and Cons of Cut & Sew Production

Choosing cut & sew production means embarking on a brand-building journey where you take full control of your products from start to finish.Below, we break down its key advantages and disadvantages.

Pros

- Unlimited customization: You are not limited by standard fits or fabrics. You can create unique silhouettes (such as convertible cuffs), use special eco-friendly fabric blends, and achieve all‑over prints that are impossible with blank T‑shirts.

- High brand value & uniqueness: Since products are built from scratch, you control every detail, including custom neck labels, hangtags and packaging. This distinctiveness allows you to charge higher retail prices and build strong customer loyalty.

- Superior quality control: You set your own quality standards. By choosing raw materials and overseeing production, you ensure softer handfeel and more durable construction than generic wholesale goods.

- Lower unit cost & higher profits: Although upfront investment is higher, unit costs drop significantly in bulk production. The production cost of a custom T‑shirt is often lower than buying a premium blank T‑shirt plus printing, leading to much better profit margins.

- Intellectual property ownership: You own the “recipe” for your products. Patterns, tech packs and size charts are all your property. This means competitors cannot easily copy your brand’s unique fit, unlike printing on off‑the‑shelf T‑shirts.

Cons

Higher barrier to entry (risk, time & capital): The main trade‑off is operational complexity. Unlike print‑on‑demand, cut & sew requires upfront money for MOQs and sampling, plus patience for a 3–4 month development cycle. You also take on the financial risk of holding inventory before sales.

Is Cut and Sew Right for Your Kids’ Clothing Business?

If you are serious about building a professional children’s clothing brand, custom cut and sew is the definitive path forward. It empowers you to select premium fabrics like organic cotton, engineer thoughtful fits for growing bodies, and command premium retail prices. This distinction is exactly what separates true fashion labels from generic T-shirt shops.

However, if your immediate goal is to test graphic concepts with minimal capital, utilizing standard blanks via Print-on-Demand is a safer short-term strategy. While this approach sacrifices deep customization, it allows you to launch without inventory risk.

Once you are ready to scale, transitioning to custom cut and sew is a strategic investment. It grants you full product ownership, healthier profit margins, and the rigorous quality control necessary to win parents’ trust.

How to Find a Reliable Cut & Sew Manufacturer for Children’s Clothing

Finding a reliable cut & sew manufacturer for kids’ wear is far more than just searching for a “factory”. What you need is a partner that understands strict safety standards such as CPSIA and provides certified fabrics like GOTS organic cotton.

For new brands, the biggest challenge is often finding a supplier that delivers high-quality production without setting unaffordable minimum order quantities (MOQs) that tie up all your working capital.

HAPA is your ideal production partner.We specialize in B2B children’s apparel manufacturing, combining boutique-level craftsmanship with flexible low MOQs. This allows you to launch your own custom collection without taking on heavy financial risk.

From sourcing eco-friendly fabrics to precise pattern making and grading, HAPA takes care of the complex production details — so you can focus on building and growing your brand.

3 Key Tips for Working With Cut & Sew Manufacturer

Below are quick guidelines to help you build a successful partnership with apparel manufacturers:

- Experience & Expertise: Choose a manufacturer with a proven track record in producing your specific type of product. Review their portfolio and client list to evaluate quality and reliability.

- Certifications: If sustainability and ethical production matter to your brand, look for kidswear manufacturers with relevant certifications such as GOTS, WRAP, SA800 or OEKO‑TEX. These certifications ensure responsible sourcing, safe raw materials, and compliance with environmental and labor standards.

- Request Samples: Always ask for pre-production samples before placing a bulk order. Manufacturers can provide ready-made samples from their existing line that closely match your design in style and material, or create custom samples specifically for your project.

Conclusion

This covers everything you need to know about cut & sew apparel production.Moving from basic sewing work to professional cut & sew manufacturing is what truly separates hobbyists from established, professional fashion brands.

You don’t have to go through this complex process alone.At HAPA, we are committed to turning your creative vision into high-quality products that fit real market needs.With our industry-leading low MOQs, certified organic fabrics and full end-to-end production support, we help you launch boutique-quality collections with ease — no heavy risks required.

Say goodbye to plain, generic fabrics.Let’s work together to build unique, standout pieces for your brand.

FAQ

What are cut and sew manufacturers?

Cut and sew manufacturers create garments from scratch based on your specific design requirements. Unlike “print-on-demand” services that use pre-made blank t-shirts, cut and sew starts with raw fabric. The manufacturer cuts the fabric patterns and sews them together. This process allows for total customization of fit, fabric, and style.

Is cut and sew more expensive than wholesale blanks?

Yes, the upfront cost is higher than buying wholesale blanks. You must pay for pattern making, sampling, and grading sizes. However, the final product has a higher perceived value because it is unique to your brand. Over time, the cost per unit can decrease significantly as your order volume increases.

What is the typical MOQ for cut and sew kidswear?

The industry standard Minimum Order Quantity (MOQ) is usually between 300 to 500 pieces per style. This volume is necessary for the factory to cover the setup costs. However, some manufacturer partners like HAPA offer lower, flexible MOQs to help emerging brands launch their first collections without overstocking.

Can I do cut and sew for a small clothing line?

Yes, absolutely. Many small clothing lines start with cut and sew to establish a unique brand identity. The key is to budget for the initial development costs and find a manufacturer willing to work with startups. Working with a supportive partner like HAPA makes this process accessible for small businesses.